Battery Management System

(Project finished in 2015)

Description

Communication protocol

Fast charging

procedure

Central unit (prototype)

Host protocol

Setup utility program for PC

Downloads

The Lithium batteries have to have monitoring system in order to avoid damage of the battery as well as to improve performance and lifetime of the battery. In this BMS (battery management system) the cell module monitors the voltage of the cell and sends data to central unit whenever the cell voltage is out the limits (too high or to low) or when it is polled.

All the software has been created in assembly

language without any third party's software. The cell module software has been

written using MPASM assembler and the central unit software has been written

using ASM30 assembler. In other words, avoiding external libraries minimizes

risk of software failure in interrupt driven firmware.

The software has been thoroughly tested, especially cell module. Special care

has been taken on abnormal situations, e.g. wrong commands sent, too many

characters in the command line, wrong baud rate set in central module,

accidental reset, etc.

The watchdog has been used in both modules (cell module and central unit) and in

cell module the watchdog timer has been used in order to clear receiving buffer

in case of lost connection between central unit and cell modules, as well as it

is used to send the alarm message automatically, if the cell module has not been

polled.

Because of watchdog timer, the maximum time delay between two successive

characters inside one command must be shorter than watchdog delay (2.3s),

otherwise the received characters will be purged from the input buffer.

The cell modules are connected in daisy chain and the messages are transferred at speed of 9600bps. The first cell module in the battery has been mounted on the most positive cell.

Here's electrical drawing of the cell module:

Where J1 is connected to cell positive, J2 is connected to cell negative pole, J3 is daisy chain input (from previous cell or from central module) and J4 is daisy chain output.

Transistor Q1 is used for bleeding the cell when

it reaches programmable threshold point. Resistor R1 has to be chosen according

to the nominal cell voltage and allowed power dissipation; recommended value is

8.8 Ohms for LiFePO4 cells and 8.2 Ohms for LiPo cells. Large cells need bigger

bleeding current and this cell module can bleed current up to 1A (with R1

resistor on the heat sink). The advantage of bigger bleeding current is that the

balancing process will take less time, but more heat will be dissipated, the

bigger R1 is - less heat will be produced but the balancing will take longer

time.

The light emitting diode D1 with resistor R6 can be omitted as is used only to indicate

bleeding process, which can be indicated on central module too.

The command to the cell module is received through resistor R7 and the cell sends the messages through resistor R4 and transistor Q2 in common base mode, which is used for level shifting.

Note: The first cell in the chain has smaller resistors R7 (75 Ohms) and R8 (470 Ohms) and is connected to central module via optocoupler in such way that the emitter of the optocoupler is connected to J3 and the collector is connected to pin J1.

Major advantage of this cell module is very low

current consumption in standby mode and good accuracy (+/-5mV for LiPo, +/-3mV

for LiFePO4). When it is not polled, the module draws average current

less than

6ľA from LiPo cell, which can be

even less than 3ľA on LiFePO4 cell. In other words, the cell module draws in

total les than 80mAh per year.

The low power consumption has been achieved by keeping the microcontroller in

sleep mode, leaving running only watchdog timer and enabling interrupt on pin

GP0 (command input). In sleep mode the microcontroller has been waked up every

~2.3 second when it measures the voltage and sends data out if voltage of the

cell is out of limits (Hi/Lo alarm).

Of course, the microcontroller has been waked up when any data comes in through

GP0 port too.

The voltage of the cell

has been measured in such way that the reference voltage of the A/D converter is

the cell and the voltage of the reference voltage has been converted through

10bit A/D input, using oversampling.

The input is sampled 16 times and the result is rounded to 12 bits.

Oversampling is chosen not only for increasing the resolution, it filters the

transients or glitches too.

The cell module sends (when is polled) the digitized value of the reference voltage, which is reciprocal to cell voltage. The central unit has to calculate the cell voltage from this value. The formula is:

Ucell = Uref * 4096 / ADref

Where ADref is digitized

reference voltage (result of A/D conversion).

The calibration constant is Uref*4096 and it is stored in nonvolatile

microcontroller's memory as well as other three values: High Alarm voltage, Low

Alarm voltage and Bleeding Threshold voltage. These parameters of the cell

module can be easily changed with appropriate commands send to the module.

Note: As the reference voltage is 2048mV, it is obvious that default

calibration constant is 0x800000, decimal: 8388608.

It is obvious that increased reference voltage means increased accuracy. The

reference voltage must be less than the minimal cell voltage too.

Assuming minimal cell voltage 2.5V, 2.048V reference voltage gives best

resolution and accuracy...

The central module (when

it is initialized) has to read calibration voltages for all cells in the chain

in order to calculate cell voltages. It is advisable to keep the cell

calibration constants in the central module in order to reduce the communication

with the cells.

The central module doesn't need these constants if it has no display, i.e. if it is

used only for alarming. Without these constants, the central module is still

able to get status of every cell and indicate hi/lo voltage alarms etc. The cell

modules executes bleeding when needed (during charging the battery or during

regenerative braking).

In addition, the cell module checks the cell voltage at least every ~2.3 seconds

(WDT wakeup) and sends the voltage with the status in case of alarm (hi/lo voltage) without

polling. In other words, the cell module sends the status in case of alarm and

when it has not been waked up due communication (which resets the watchdog

timer).

The communication with the cell module is made through daisy chain and the communication protocol is explained here.

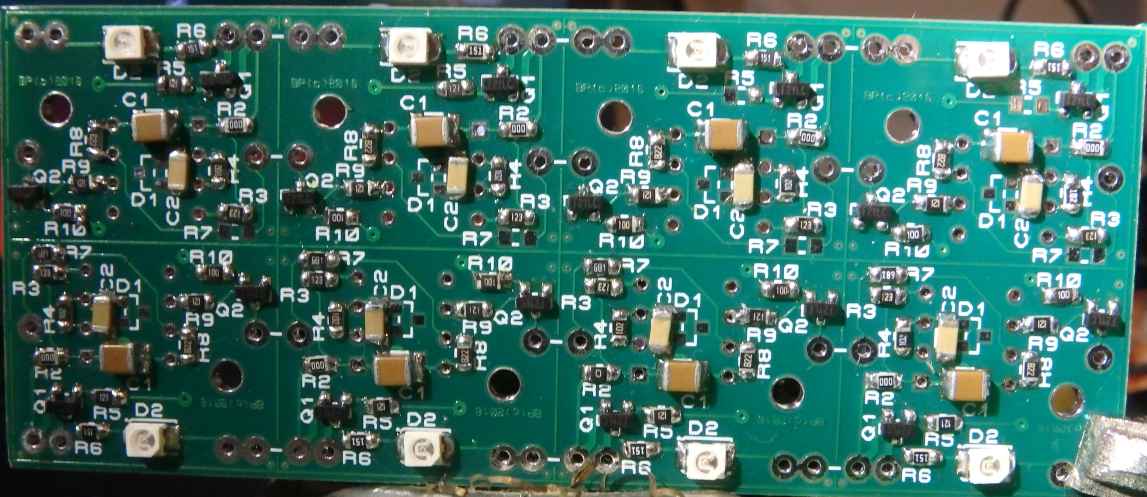

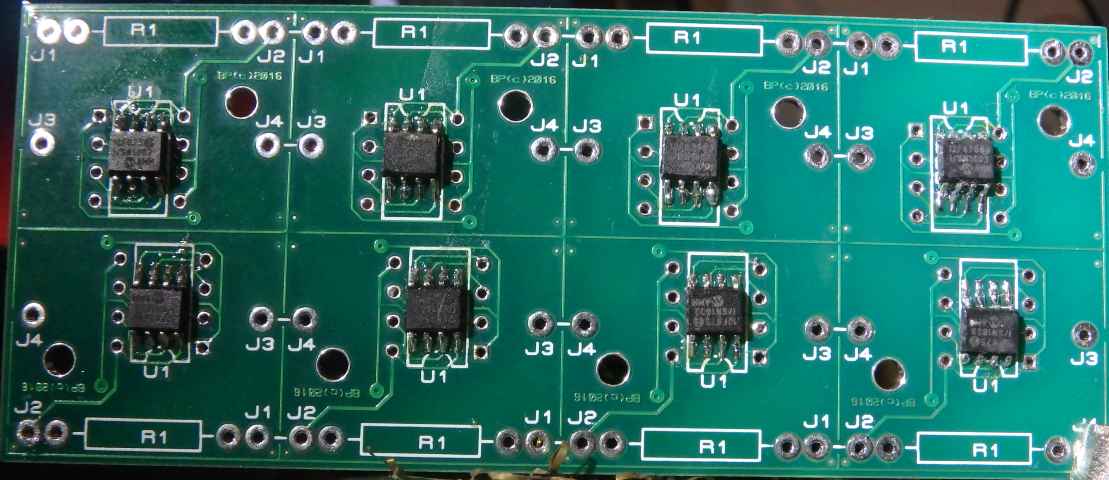

Assembled cell modules: